Maintenance and repair

Maintenance levels CHP ASV 14, 15, 20, 21

The routine inspection, maintenance and possible repairs of ASV-cogeneration plants are designed as a modular system. All components are optimized for 6,000 hours of operation after which a detailed maintenance is required. This means that usually an annual maintenance is required.

The following steps are:

Inspection and maintenance level 1:

every 6.000 operating hours or at least once a year

Inspection and maintenance level 2:

every 12.000 operating hours or every second

If your CHP has less than 6,000 operating hours per year, to ensure service life it is required to carry out an inspection and maintenance once a year. Maintenance level 2 will always be executed in addition to maintenance level 1.

Repair

Certain repair kits for the cogeneration plant must be replaced not by fixed times, but set according to the degree of deterioration. At the ASV-cogeneration plants following repair routines are dependant on the wear and performance:

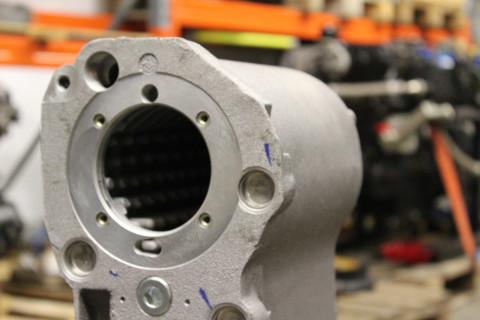

Repair exhaust gas heat exchanger

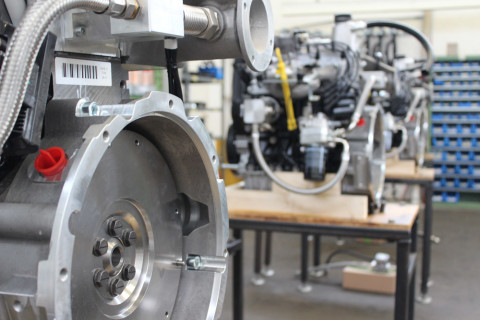

Repair engine overhaul

With CHP ASV 40 every 3,000 operating hours or at least once a year, a detailed maintenance is required. The inspection and maintenance level 2 is carried out every 6,000 operating hours or every second maintenance.