CHP Service

All service and maintenance of cogeneration plants branded Energiewerkstatt™ must be carried out by qualified sales and service partners, service partners or the pure Energiewerkstatt™ customer services.

All information about routine maintenance, inquiry and notification:

Telephone +49 511 / 949 74 – 65 oder – 66

Fax +49 511 / 949 74 – 74

E-Mail service@energiewerkstatt.de

For reliable and durable operations of a cogeneration plant, solid maintenance and a good service are required.

We want to make the routine work as comfortable and easy as possible and have therefore put all work together in a maintenance kit, which we would like to present here.

Maintenance and repair

Maintenance levels CHP ASV 14, 15, 20, 21

The routine inspection, maintenance and possible repairs of ASV-cogeneration plants are designed as a modular system. All components are optimized for 6,000 hours of operation after which a detailed maintenance is required. This means that usually an annual maintenance is required.

The following steps are:

Inspection and maintenance level 1:

every 6.000 operating hours or at least once a year

Inspection and maintenance level 2:

every 12.000 operating hours or every second

If your CHP has less than 6,000 operating hours per year, to ensure service life it is required to carry out an inspection and maintenance once a year. Maintenance level 2 will always be executed in addition to maintenance level 1.

Repair

Certain repair kits for the cogeneration plant must be replaced not by fixed times, but set according to the degree of deterioration. At the ASV-cogeneration plants following repair routines are dependant on the wear and performance:

Repair exhaust gas heat exchanger

Repair engine overhaul

With CHP ASV 40 every 3,000 operating hours or at least once a year, a detailed maintenance is required. The inspection and maintenance level 2 is carried out every 6,000 operating hours or every second maintenance.

Extent of work

At every inspection, the CHP will be reviewed in accordance with optimal defined diagnostic routines.

In addition, basic maintenance work such as renewing the spark plugs. All necessary materials and labour costs other than oil and coolant are included – the disposal of used oil and oil filter is also included. On new spare parts you get 12 months warranty, if it is not subject to wear.

The individual steps can be found in the following table.

Overview of our service packages

| ASV 21, 20, 15 and 14 |

|---|

| Inspection and maintenance level 1 (every 6.000 operating hours) |

| Inspection and maintenance level 1 und 2 (every 6.000 operating hours) |

| Repair – exhaust gas heat exchanger |

| Repair – engine overhaul |

| Maintenance and Service | Works |

|---|---|

| Inspection and maintenance level 1 (every 6.000 operating hours) | Control and monitor (every 6,000 operating hours) operating values; Visual inspection Gas Range; Check oil reserve; Change spark plugs; Change the oil filter; Dispose of old oil filter; Measure exhaust backpressure in the engine; Change purge; Replace air filters; Condensate trap rinse; Clean heating circuit filter; Check tightness of the oil and water circuit in CHP; Visual inspection of the exhaust system; Check the engine water pressure and if necessary top up with ASV 21 or 40 (coolant will be charged if necessary); Check the oil level; Check expansion vessel; Check Surveillance-, storage and control functions; Exhaust gas sensor - function control; Oil change at ASV 21 or 40; Timing belt and tensioner switch; Inspect and clean the gas regulator, and -ventils ™ mixer; Switch ignition cable; Check the harness for integrity; Check oil mechanism; Check PWT spreads; Ensure disposal of used oil / used oil canisters; Replace engine water pump; (Oil for the reserve tank is charged separately according to the required amount.); Inspect and clean the oil pressure equalization hose; Heating water analysis; Emission testing |

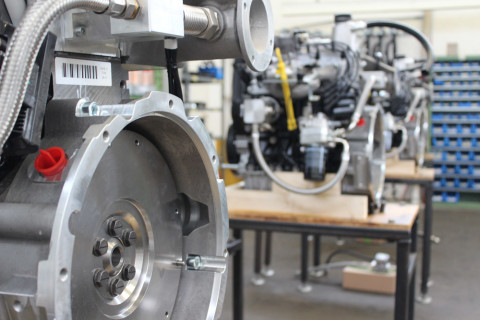

| Inspection and maintenance level 2 (every 12.000 operating hours) | Exchange endshield ASV 21; Replace water pressure switch; Exchange the gas mixer housing; Automatic gas / air mixture control (lambda control) |

| Repair- exhausted gas heat exchanger | Upkeep-measure exhaust for gas, heat exchanger exhaust and backpressure on the engine; Check exhaust hose; Change exhaust gas heat exchanger at ASV 21; Change catalyst; Emission testing |

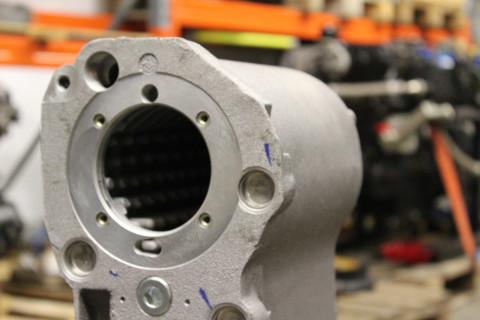

| Repair- engine overhaul | Expand upkeep-engine overhaul old motor and install the repaired engine; All existing CHP attachments on repaired engine plant; Insert new seals at engine swap; Emission testing |

(Deutsch) Wartungen unserer Anlagen

Service Replacement Parts for your CHP

You will receive all original Energiewerkstatt™ ASV-replacement parts and consumables. To ensure proper operation of Energiewerkstatt™ CHP and also taking into account any warranty considerations using the original Energiewerkstatt™ ASV service replacement parts is strongly recommended.

Orders can be placed as follows:

Telephone: +49 511 / 949 74 – 0

Fax: +49 511 / 949 74 – 74

E-Mail: service@energiewerkstatt.de

We ensure that you can continue to reliably produce heat and electricity supply.

Documents for mineral oil tax refunds (Germany only)

As an operator of a cogeneration plant to ensure reimbursement of fuel taxes from Hauptzollamt (principal customs office) you must submit the following documents:

Declaration of Tax Relief

With this declaration and the TDS of your CHP you confirm to the Hauptzollamt (principal customs office) that you meet the requirements for reimbursement. This statement you must make only once.

Declaration of tax relief (259 KB)

Specifications ASV 40 (502 KB)

Specifications ASV 30 (502 KB)

Specifications ASV 21 (502 KB)

Specifications ASV 20 (502 KB)

Specifications ASV 15 (502 KB)

Specifications ASV 14 (502 KB)

Specifications ASV 18, 2007 (84 KB)

Specifications ASV 15, 2006 (256 KB)

Application form for principal customs office (Hauptzollamt) (Germany only)

The application form is available on the Customs website (www.zoll.de)

Request from customs office 1132

Request from customs office 1134

(Status 03.06.2014 – All Rights Reserved. The statutory regulations shall apply.)

Calculation

For a successful application you need the amount of gas/fuel that was consumed in the CHP. If you do not have a separate gas meter for the CHP, you can determine the amount of gas here. The calculation is converted to full- load hours. Thus, the calculated gas consumption is not always above the actual gas consumption.

Remote Querying

Our cogeneration plants are equipped with a modem. Access from anywhere via the internet and control your CHP or see the status of your ASV online.